A solution that reinvents internal quality control

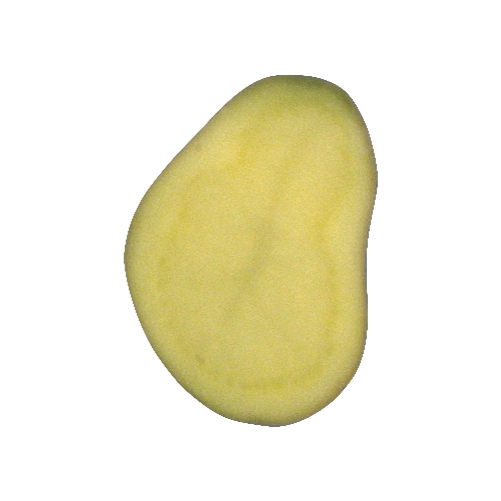

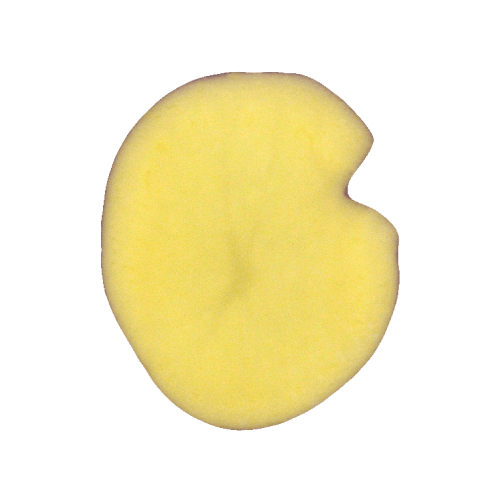

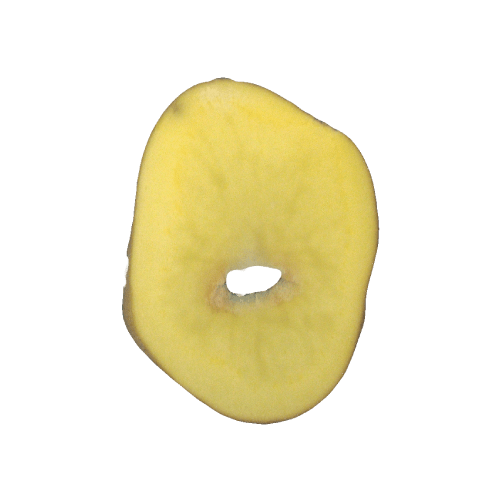

#1 - DETECTION OF INTERNAL DEFECTS

Intracelp analyses each tuber thanks to its vision technologies and artificial intelligence.

It automatically identifies internal defects and diseases, guaranteeing a precise and reproducible evaluation of internal quality.

Anticipate quality issues, save time on manual inspections and make your decisions based on objective data.

#2 - SIZE ANALYSIS

Intracelp accurately measures the size of each potato in order to assess the homogeneity and regularity of your samples.

The analysis is automated and offers greater precision than any manual evaluation, providing you with reliable and comparable data to support your decisions.

Defects and diseases detected

Greening

Growth cracks / Misshaped

Damaged

Punctures / Galleries

Rusts

Hollow hearts

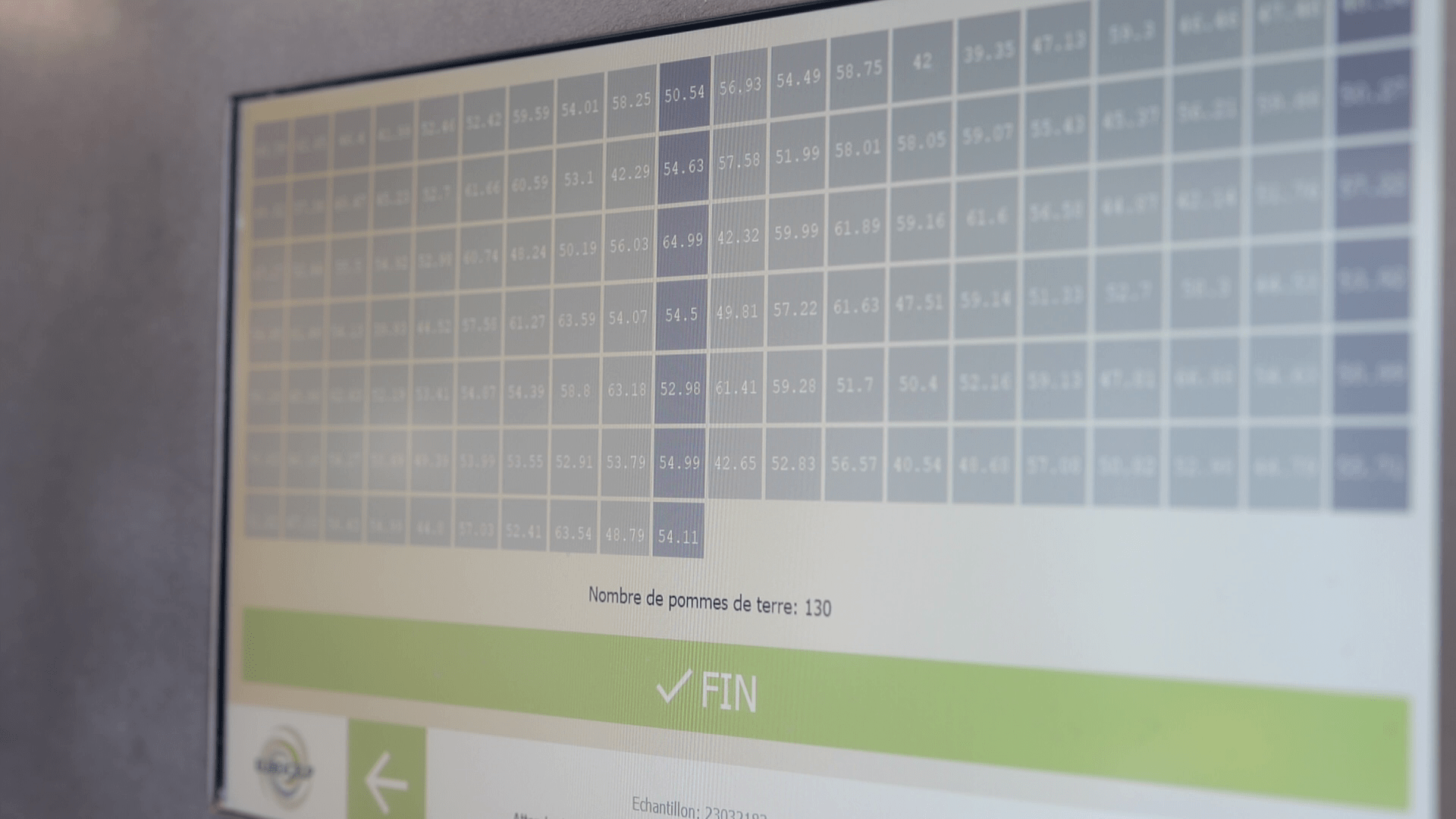

Detailed results in one click

#1 - Immediate consultation

After analysing your sample with Intracelp, easily access the results from the customer platform or the mobile application. You thus have your data in real time, wherever you are.

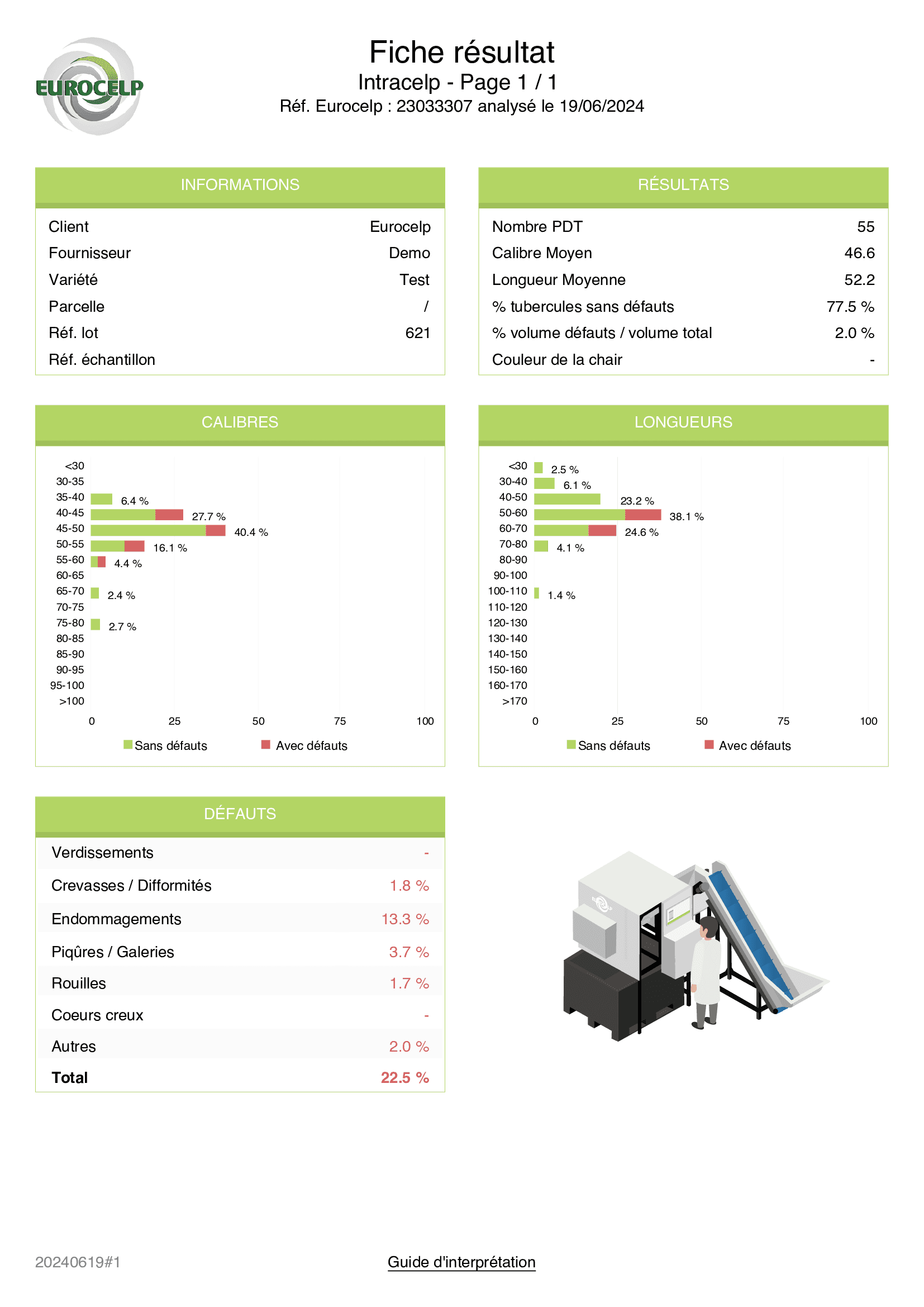

#2 - Complete and precise report

Each analysis automatically generates a detailed PDF sheet that brings together all the information of the sample with great precision. This document becomes a reliable reference for your quality follow-ups.

#3 - Sharing and valorisation

In just a few clicks, you can share your reports with your producers, partners or clients. A simple and effective way to highlight the quality of your lots and to strengthen transparency in your commercial exchanges.

The advantages of Intracelp for your activity

100x

More efficient than manual control

Absolute precision

Consistent results, whatever your production conditions.

Intracelp guarantees reliable and reproducible analysis, without variation. You compare your data with confidence to improve your productivity.

Consistent results, whatever your production conditions.

Intracelp guarantees reliable and reproducible analysis, without variation. You compare your data with confidence to improve your productivity.

600h

Hours saved on average per year and per operator

Expertise enhanced

Free up time for your teams and enhance their know-how.

By automating quality control, Intracelp reduces repetitive tasks and allows your collaborators to focus on strategic analyses and high added-value decisions to efficiently manage production.

Free up time for your teams and enhance their know-how.

By automating quality control, Intracelp reduces repetitive tasks and allows your collaborators to focus on strategic analyses and high added-value decisions to efficiently manage production.

÷10

Average time to train a new operator

Ease of use

A tool accessible to everyone, without prior expertise.

With Intracelp, no need to be a quality control specialist: the interface is intuitive and quick to learn.

Training a new operator takes less than one hour, which makes it easy to delegate the analysis, even during peak activity.

A tool accessible to everyone, without prior expertise.

With Intracelp, no need to be a quality control specialist: the interface is intuitive and quick to learn.

Training a new operator takes less than one hour, which makes it easy to delegate the analysis, even during peak activity.

Beyond human capabilities

Reinvented control

Carry out your analyses in just a few minutes, without human limitations.

No fatigue, no variation: each sample is analysed with the same rigour, ensuring high-quality control and an immediate gain in productivity.

Carry out your analyses in just a few minutes, without human limitations.

No fatigue, no variation: each sample is analysed with the same rigour, ensuring high-quality control and an immediate gain in productivity.